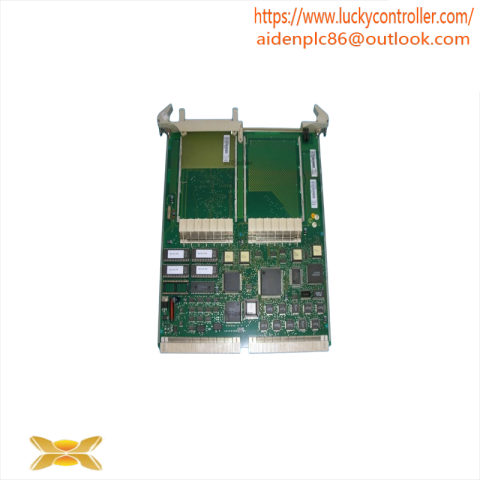

KUC755AE117 3BHB005243R0117 is a standard digital/analog input/output (I/O) unit for ABB AC 800PEC controller. It is a core component of 800xA automation platform. Its main functions include:

Signal acquisition: connect field sensors (such as temperature, pressure, flow) to collect analog/digital signals.

Control output: drive actuators (such as valves, motor contactors) and output switch or analog control signals.

Electrical isolation: full isolation between input/output channels and between channels and ground, with strong anti-interference ability.

Hot-swap support: allows module replacement while the controller is running (system support must be confirmed).

Hardware specifications and interfaces

1. Physical structure

Size: standard 19-inch rack design (width 45mm, height 100mm).

Slot type: inserted into the I/O slot of the AC 800PEC controller backplane (marked as DI/DO/AI/AO).

Protection level: IP20 (installed in the control cabinet), optional IP54 protection box (suitable for outdoor or dusty environment).

Operating temperature: -20°C ~ +60°C (industrial-grade design, suitable for harsh environments).

Indicator lights and diagnostics

Module status light:

Green always on: module is operating normally.

Red flashing: channel fault or configuration error.

Channel indicator light:

DI/DO: green = signal activated, off = signal not activated.

AI/AO: yellow = channel overload or disconnection.

4. Expansion capability

Optional plug-in modules:

High-density I/O module: add 32DI/32DO (model: KUC755AE117 3BHB005243R0117).

Thermocouple input module: supports K/J/T type thermocouples (range -200°C ~ +1372°C).

RTD input module: supports PT100/PT1000 temperature sensor (accuracy ±0.1°C).

Functional features

1. Signal processing capability

Digital input:

Supports wet contact (external power supply) or dry contact (internal power supply).

Anti-shake filter: Configurable filter time (0.1ms~10ms) to eliminate mechanical contact jitter.

Digital output:

Relay output: supports AC 250V/2A or DC 30V/0.5A load.

Transistor output: supports high-speed pulse output (such as stepper motor control).

Analog input:

Automatic range calibration: supports automatic recognition of 4-20mA/0-10V signals.

Wire break detection: When the signal line is disconnected, the module outputs an alarm signal.

Analog output:

Ramp control: Configurable output change rate (such as 1V/s) to avoid actuator impact.

2. Safety and redundancy

Channel redundancy: Key signals can be configured as dual-channel redundancy (such as emergency stop button).

Watchdog timer: Monitors module communication status and automatically resets when timeout.

Safety certification: Meets IEC 61508 (SIL 2) and IEC 62061 (PL d) standards.

3. Communication interface

Internal bus: Communicates with the controller via the AC 800PEC backplane bus (bandwidth 100Mbps).

External interface:

1 × RS485 debug port (for module parameter configuration).

1 × test button (manually trigger digital output test).

Configuration method and tools

1. Hardware installation

Slot selection:

Digital modules are inserted into DI/DO slots, and analog modules are inserted into AI/AO slots.

Avoid inserting different types of modules together (such as DI and AI sharing the same slot).

Wiring specifications:

Digital input:

Source input: external power supply +24V, signal line connected to module input terminal.

Sink input: module power supply +24V, signal line connected to external contact.

Analog input:

4-20mA signal: connected to the module in series (pay attention to polarity).

0-10V signal: connected to the module in parallel (common ground connection).

Grounding treatment:

The analog signal line uses shielded twisted pair, and the shielding layer is grounded at one end (module side).

2. Software configuration

Tool: ABB Control Builder Safe (version ≥V6.1).

Steps:

Create a project: Create a new AC 800PEC controller project.

Add I/O modules:

Scan the backplane in the hardware configuration and automatically identify KUC755AE117 3BHB005243R0117.

When adding modules manually, select the model and configure the slot position.

Channel mapping:

Bind digital inputs to controller internal variables (such as %IX0.0 corresponds to DI0).

Bind analog inputs to floating-point variables (such as %IW0 corresponds to AI0, unit mA or V).

Parameter setting:

Set the digital input filter time (such as 2ms).

Configure the analog input range (4-20mA or 0-10V).

Download and test:

Download the configuration to the controller via Ethernet.

Use ABB 800xA Diagnostic Tool to monitor channel status.

Typical application scenarios

1. Industrial process control

Scenario: Chemical reactor temperature/pressure control.

Configuration:

AI0-AI3: Connect PT100 temperature sensor (4-20mA output).

AI4-AI5: Connect pressure transmitter (0-10V output).

AO0-AO1: Control heating valve and cooling valve (4-20mA signal).

DI0-DI3: Connect emergency stop button and liquid level switch.

Effect: Realize closed-loop control of temperature/pressure, response time <500ms.

2. Mechanical automation

Scenario: Multi-axis synchronous control of packaging machinery.

Configuration:

DI0-DI7: Connect photoelectric sensor (detect packaging position).

DO0-DO7: Drive stepper motor driver (pulse + direction signal).

AI0-AI1: Connect encoder feedback (analog output).

Effect: Realize packaging positioning accuracy ±0.1mm, speed 200 packs/minute.

3. Energy management

Scenario: Optimization of photovoltaic power station power.

Configuration:

AI0-AI3: Connect photovoltaic string current sensor (4-20mA).

AO0-AO1: Control DC/DC optimizer (0-10V signal).

DI0-DI1: Connect inverter start/stop signal.

Effect: Improve photovoltaic power generation efficiency by 5%~10%.

Troubleshooting and maintenance

Diagnostic tools

ABB 800xA Diagnostic Tool:

Real-time monitoring of channel status (such as whether %IX0.0 is activated).

View historical alarm records (such as channel disconnection, overload).

Multimeter:

Measure digital input voltage (normal should be 24V DC ±10%).

Measure analog output current (4-20mA corresponds to 0%~100% range).

3. Maintenance recommendations

Periodic inspection:

Clean the module dust every quarter to prevent poor contact.

Check the tightness of the terminal blocks every year (avoid looseness).

Spare parts management:

Reserve 1 module of the same model as an emergency replacement.

Storage environment: temperature 0°C ~ +40°C, humidity <70% RH.

Summary

ABB AC 800PEC I/O unit (KUC755AE117 3BHB005243R0117) is a high-performance, high-reliability industrial input and output module. With its multi-channel design, high-precision signal processing and strong anti-interference ability, it is widely used in process control, mechanical automation and energy management. Pay attention to wiring specifications and parameter setting during configuration, and focus on checking channel status and grounding during daily maintenance.

Related product recommendations:

XVC724BE102 3BHE009017R0102

UFC921A 3BHE024856P201

3BHE009017R0102

UAC389 HIEE410506P104

NTAC-02 58967441E

KUC755AE105 3BHB005243R0105

TU830V1 3BSE013234R1

GRBTU-01 3BSE013175R1

LT2005-S/SP19

XVC769AE101 3BHE006373R0101

More……

There are no reviews yet.