Core Positioning and Technical Background

Product Attributes: This system is part of the ABB PCS6000 medium-voltage power conversion system, designed specifically for wind power generation (especially offshore wind power) and high-power industrial applications. It supports dynamic reactive power compensation, grid fault ride-through (FRT), and intelligent power flow control.

Power Range: Generator-side power covers 0-15MW, compatible with permanent magnet synchronous generators (PMSGs) and induction generators (IMs), with modular expansion up to 120MVA.

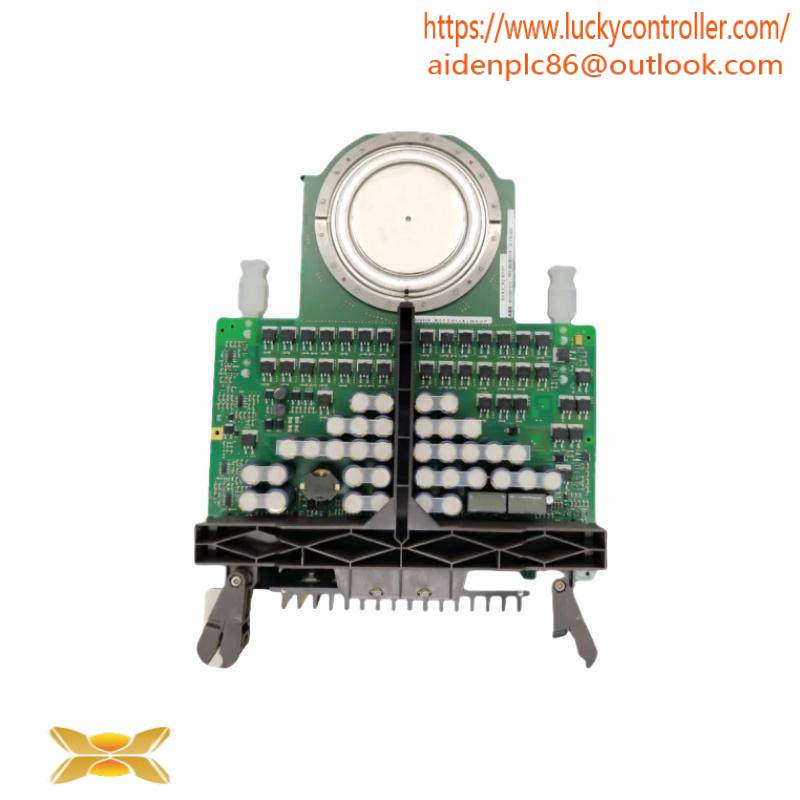

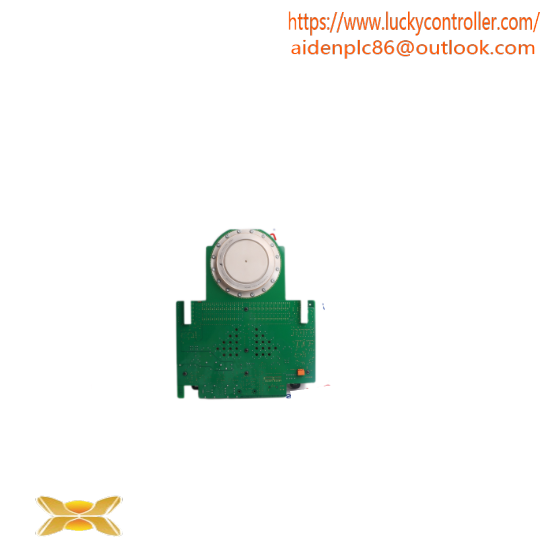

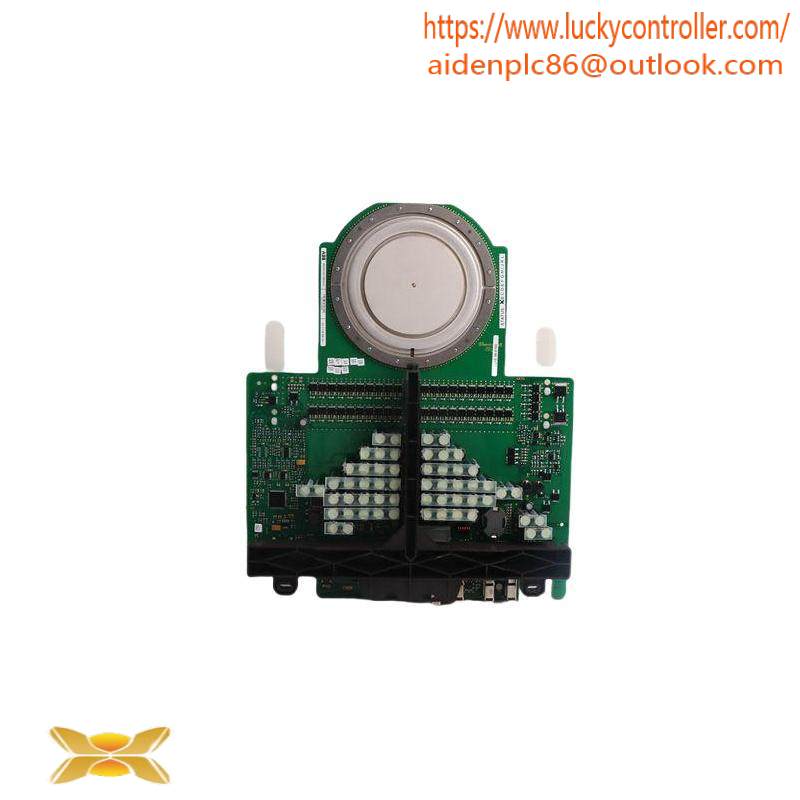

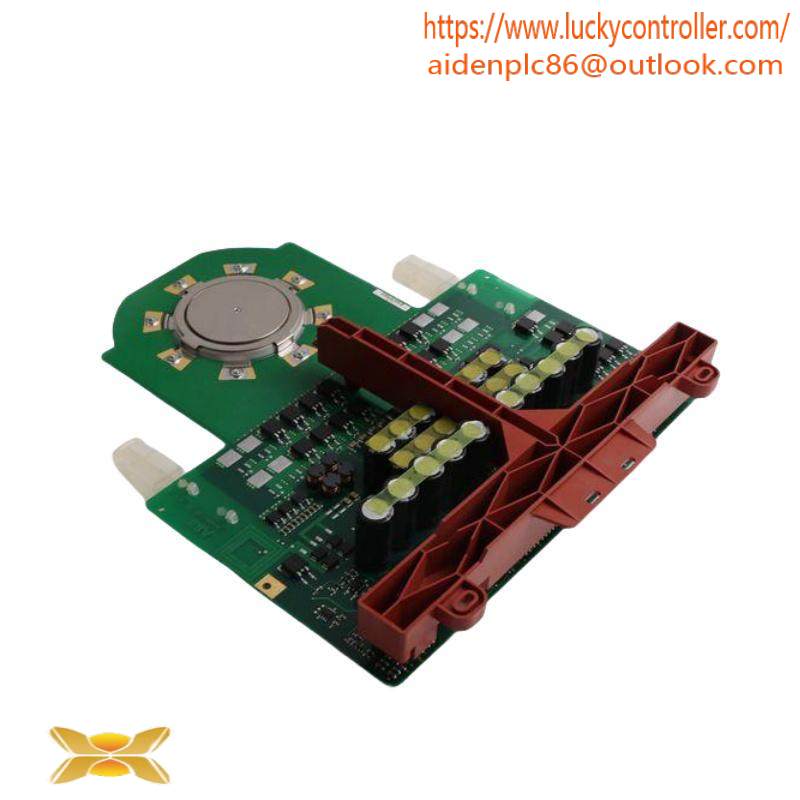

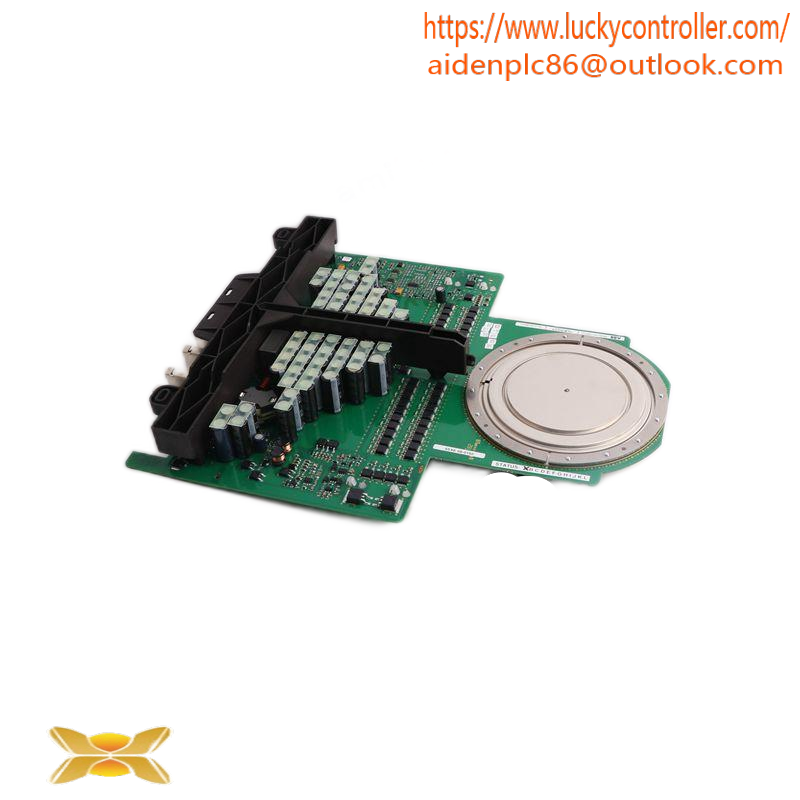

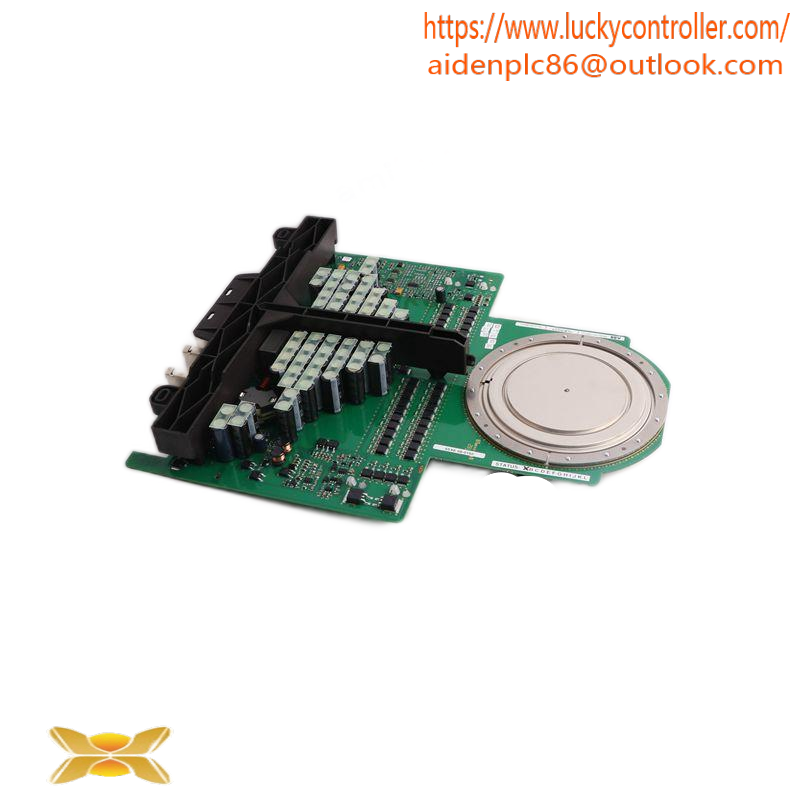

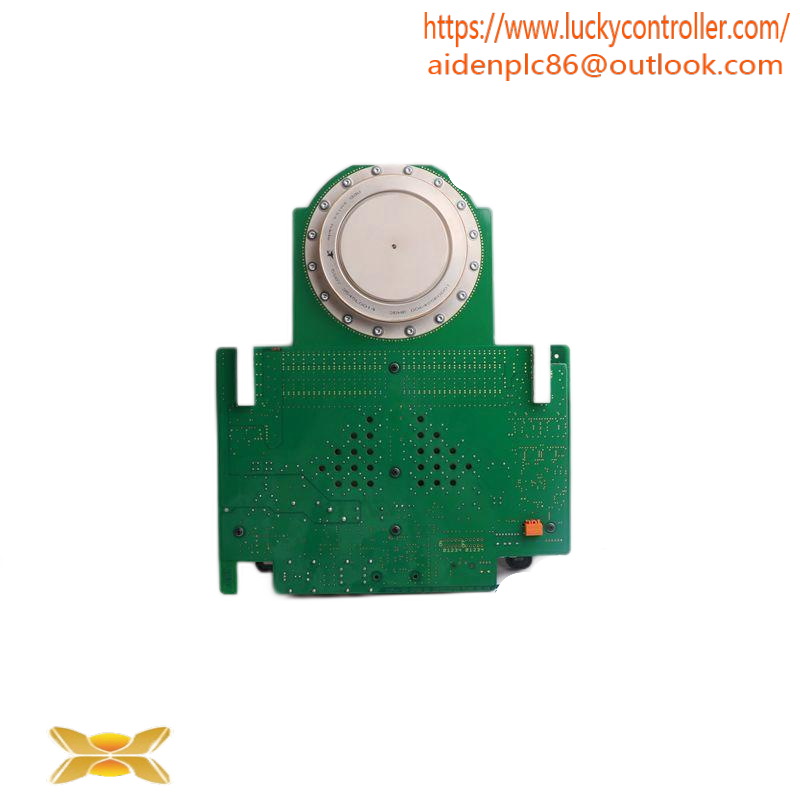

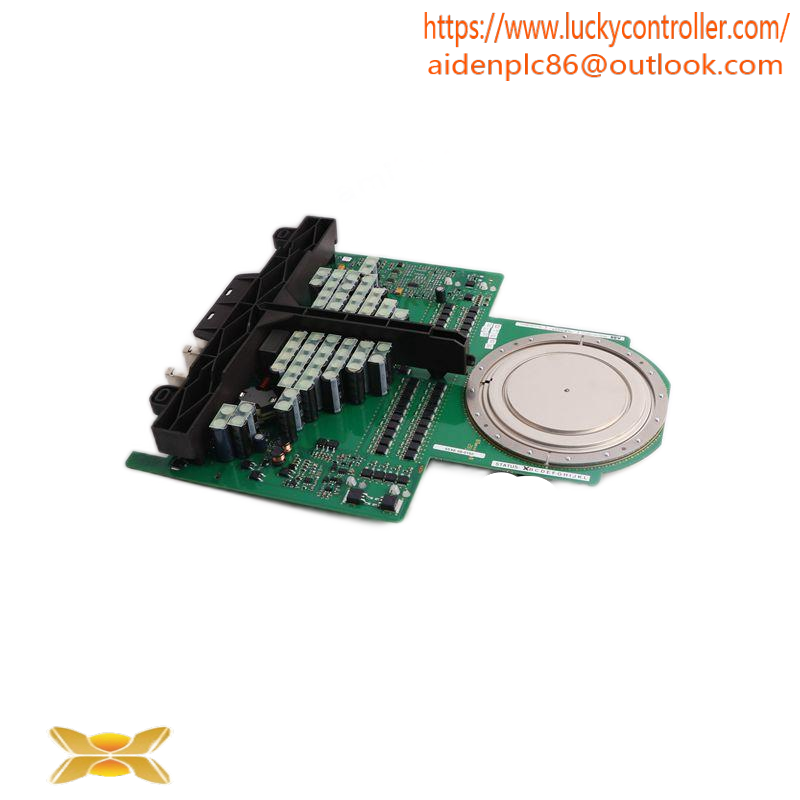

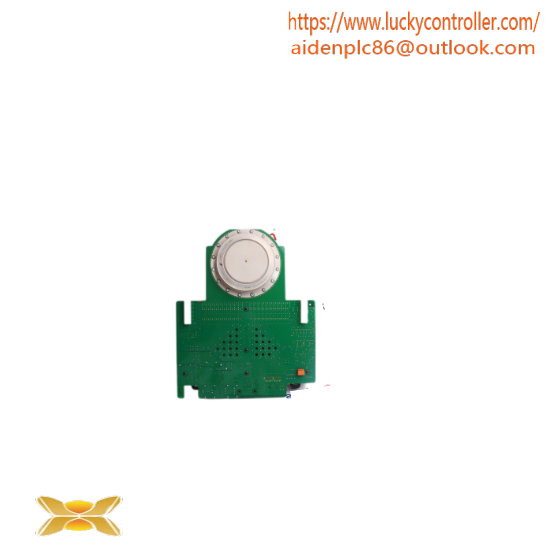

Technical Architecture: Utilizes a three-level NPC topology and IGCT semiconductor devices, enabling bidirectional four-quadrant operation with 98% efficiency. The cooling system is a closed-loop liquid cooling system with an IP54 protection rating and is suitable for operating environments ranging from -10°C to +45°C.

Key Technical Parameters

Electrical Performance:

Voltage: 0-3.4kV on the generator/grid side, supporting 50/60Hz grid frequencies.

Control Features: Generator-side PWM modulation, grid-side optimized pulse mode, support for dynamic reactive power compensation (20-100 Mvar) and fault ride-through (LVRT/HVRT).

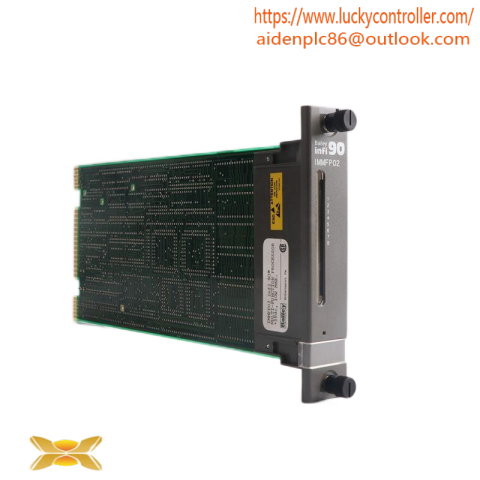

Communication Interfaces: Profibus DP, Profinet IO, Modbus TCP, EtherCat, CANopen, supporting remote VPN monitoring.

Protection Functions: Overload, short-circuit, and overvoltage protection, meeting SIL 3 (IEC 61508) and PLe (ISO 13849) safety standards, certified by DNV-GL, UL, and CGC.

Technical Features:

Power Range: Module unit power 4-120 MVA, supporting wind power applications up to 14 MW.

Voltage Levels: 10 kV to 230 kV, compatible with medium-voltage grid requirements.

Core Technology: Utilizes an IGCT (Integrated Gate-Commutated Thyristor) three-level topology, enabling bidirectional power flow and four-quadrant operation, with >98% efficiency.

Cooling System: Dual-mode closed-loop cooling (air/water), IP54 protection.

Control Unit: Integrated with the ABB AC800PEC PLC, supporting sensorless algorithms and modular expansion.

Compatibility: Deeply integrated with the ABB AC800PEC control system, water cooling system, and remote monitoring tools (such as DriveWindow).

Wind Power Application Scenarios and Advantages

Grid Compliance: Meets strict grid regulations (such as the Scottish wind farm project), ensuring grid stability through dynamic reactive power compensation (20-100 Mvar) and fast voltage control.

Offshore Wind Power Adaptability: Modular design supports nacelle or tower installation, suitable for large wind turbines up to 12 MW, reducing cable loss and installation costs.

Fault Ride-Through Capability: Maintains operation during grid faults (such as voltage sags and unbalance faults), complying with international standards such as GL-IV-2:2012.

High Reliability: SIL 3 and PLe safety certifications are achieved, with a low failure rate, proven in over 100 GW of offshore wind power projects worldwide.

Maintenance and Troubleshooting Key Points

Daily Maintenance:

Regularly check fiber connections, board tightness, and water cooling system pressure/flow.

Perform annual capacitor capacity testing, dust cleaning, and wiring tightening.

Common Troubleshooting:

Communication Failure: Check the fiber optic cables, board status, and Modbus/Ethernet interfaces within the cabinet.

Synchronization Signal Abnormality: Verify synchronous voltage stability (AB/BC/CA phases) and TV line disconnection.

Water Cooling System Alarm: Check the main circulation pump, valve status, pipeline leaks, and buffer tank pressure.

Board Failure: If AD board data verification fails, check for damage to the IGBT driver, current sensor, or fiber.

Configuration and Communication Failures

Configuration Failure: When the system is powered on, the control panel will send configuration parameters to each functional board and test the communication link. If a message such as “Unit board configuration fault” appears, check the following:

Is the communication fiber in the cabinet secure? Are the boards loose or have signs of burning?

Is the cabinet power-on sequence correct? It is recommended to power cycle the power cord.

If the fault persists, replace the board or fiber.

Communication Failure: If communication between the system control panel and the device cabinet is interrupted, check the following:

Is the fiber connection between the control panel loose? Are the boards frozen?

Use the Modbus RS485 serial port or Ethernet interface to troubleshoot communication protocol issues.

Board and Hardware Failures

Board Failure: If a message such as “Level 2 AD board fault” is detected during operation, check the following:

Board data verification failure, which may involve the IGBT driver, current sensor, etc.

If a board is loose, burned, or the fiber is damaged, replace the board or fiber.

Synchronization Failure: If the synchronization signal is lost or the frequency is abnormal, check the following:

The synchronization voltage (AB/BC/CA phases) is stable, and whether the TV line is disconnected.

Frequency failures may indicate grid voltage fluctuations or sensor problems.

Water Cooling System Abnormality

Water Cooling Failure: If the water cooling system issues a “trip” signal, check the following:

The operating status of the main circulation pump, whether the valve is open, and whether there are any leaks in the pipeline.

The buffer tank pressure, inlet valve pressure, and cooling water flow rate are within normal ranges.

If the water cooling system PLC fails or the control power supply fails, shut down the equipment immediately.

Other Common Problems

Circuit Breaker Abnormality: If a circuit breaker node experiences abnormality during operation, check for loose connections and normal node voltages.

Brake Problems: A stuck brake or coil failure may result in delayed shutdown and require adjustment or replacement.

Motor and Cable: Motor winding insulation, cable damage, or internal IGBT/rectifier bridge failures in the inverter require professional inspection.

Technical Parameters and Maintenance Recommendations

PCS6000 Features: Rated capacity ranges from 12.5Mvar to 40Mvar. It utilizes a three-level voltage source converter (VSC) and IGCT technology, supports fast dynamic reactive power compensation, and has a response time in the millisecond range.

Maintenance Tips: Regularly check board connections, fiber optic status, and water cooling system pressure and flow. Perform annual dust removal, wiring tightening, and capacitor capacity testing.

Related product recommendations:

SCYC51010 58052515G

P4LQA HENF209736R0003

CP405 A0 1SAP500405R0001

5SHY3545L0009

5SHY3545L0009 3BHE009681R0101

3BSE050091R65

PFEA112-65 3BSE050091R65

PCD235B1101 3BHE032025R1101

CI810B 3BSE020520R1

SD822 3BSC610038R1

PU512V2 3BUR001401R1

500CPU05 1MRB150081R1/E

REF542 1VCR007346 G0028

PM802F 3BDH000002R1

SYN5302A-Z,V217 3BHB006716R0217

More……

There are no reviews yet.