Core functions

High-voltage motor drive: supports 3kV/6kV/10kV medium and high-voltage AC motor speed regulation, suitable for high-power industrial equipment.

Energy optimization: energy saving is achieved through frequency conversion regulation. Typical scenarios such as flow/pressure control of fans and water pumps can achieve energy saving rates of 30%-50%.

Soft start/brake: reduce mechanical shock and extend equipment life.

Harmonic suppression: built-in filtering technology to reduce interference to the power grid.

Technical specifications and hardware configuration

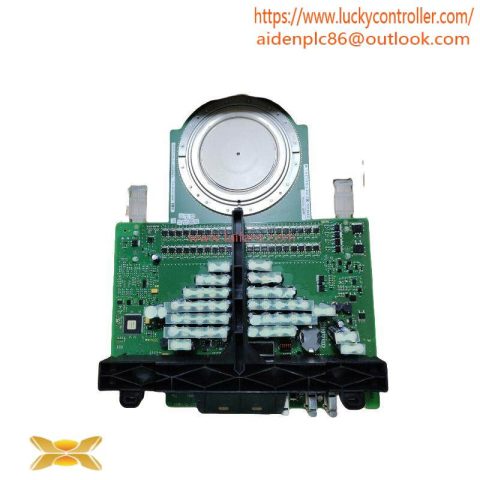

Power module

Wide voltage input design, adapted to power supply standards of different countries, with overvoltage, undervoltage, and overcurrent protection functions.

Efficient power conversion ensures the stability of the DC power supply inside the inverter.

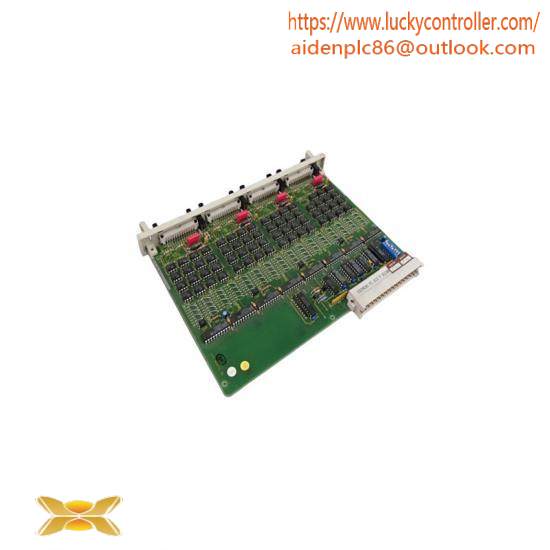

Control module

Advanced control algorithms (such as vector control, direct torque control) and high-speed processors are used to achieve high-precision motor control.

Support multiple protection functions: overload, overheating, and short-circuit protection to ensure safe operation of the motor.

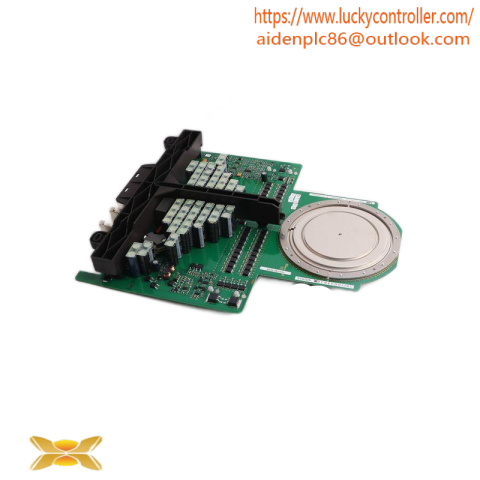

Power module

Power semiconductor devices and heat dissipation design to achieve high efficiency and low loss operation.

The rated power covers the medium and high voltage range to meet the industrial heavy load requirements.

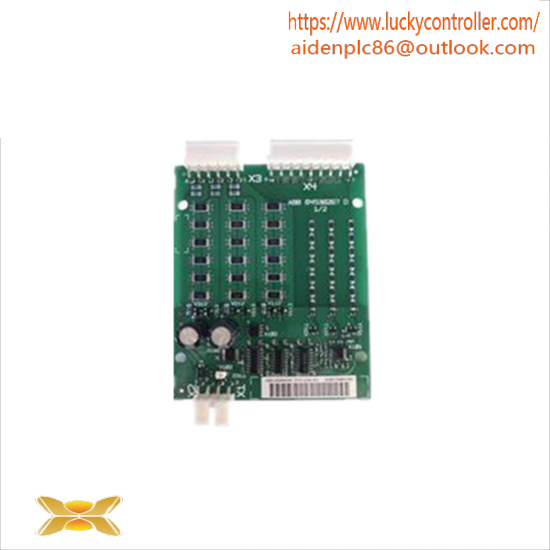

Communication and interface

Supports multiple communication interfaces such as RS-232, RS-485, Ethernet, etc., which is convenient for integration with external devices (such as DCS, PLC).

Rich I/O interfaces (digital/analog), support sensor and actuator connection, and achieve precise control.

Application scenarios

Heavy industry

High-voltage motor drive for rolling mills, mining crushers, and large compressors.

Chemical/petroleum

Frequency control of pumps, fans, and compressors to adapt to explosion-proof environments.

Power industry

Boiler feed pump and induced draft fan control to optimize power generation efficiency.

Water treatment

Speed regulation of large water pump stations to achieve efficient water supply/drainage.

Transportation and infrastructure

High-pressure fan control of subway/tunnel ventilation systems, HVAC central air conditioning chiller adjustment.

New energy

Pumped storage turbine auxiliary control, wind power variable pitch system drive.

Maintenance and troubleshooting

Daily maintenance points

Environmental inspection: Ensure that the operating environment temperature (-5℃~40℃) and humidity (<90%) are appropriate to avoid condensation.

Cooling system: Regularly clean the dust in the air duct, check the operating status of the fan, and ensure the heat dissipation effect.

Status monitoring: Observe the motor temperature, odor, abnormal sound, and check the output voltage/current balance.

Regular maintenance items

Dust removal and cleaning: Deeply remove dust from transformer cabinets, power unit cabinets, and control cabinets.

Component inspection: Tighten screws and bolts, check the aging of insulation parts, and replace capacitors and fans when necessary.

Performance test: Use an oscilloscope to detect the output stability of the switching power supply and measure the waveform of the drive circuit.

Replacement cycle of key components

Fan: Replace after 2-3 years of continuous operation.

Electrolytic capacitor: Detect capacity every year and replace when the capacity decays by more than 20% (design life is about 5 years).

Compatibility and scalability

Interface compatibility: supports standard interfaces such as RS-232, RS-485, Ethernet, etc., and can be seamlessly connected to the industrial bus system.

Analog expansion: ABB series analog expansion modules can be optionally equipped to enhance the analog signal input/output capabilities, suitable for process control (such as temperature and pressure regulation) and mechanical control (such as position and speed control).

Programming flexibility: programmable control chips are used to support custom control logic and algorithms to adapt to complex industrial scenarios.

Summary

ABB UFC921A 3BHE024856P201 high-voltage inverter module is a high-performance and high-reliability industrial-grade power electronic equipment, widely used in high-voltage motor drive scenarios. Its technical advantages are reflected in:

Efficient energy saving: significant energy consumption reduction is achieved through frequency conversion regulation.

Stable and reliable: built-in multiple protection functions, adaptable to harsh industrial environments.

Flexible expansion: supports a variety of communication interfaces and expansion modules for easy system integration.

Related product recommendations:

PM866A 3BSE076359R1

1TGE120021R0010

3BHB007211R0102

XVC768AE102 3BHB007211R0102

3BHE030410R3011

PPD117A3011 3BHE030410R3011

3BHE004573R0143

UFC760BE143 3BHE004573R0143

3BSE011181R1

3BSE050092R65

PFEA113-65 3BSE050092R65

3BSE028144R0065

More……

There are no reviews yet.