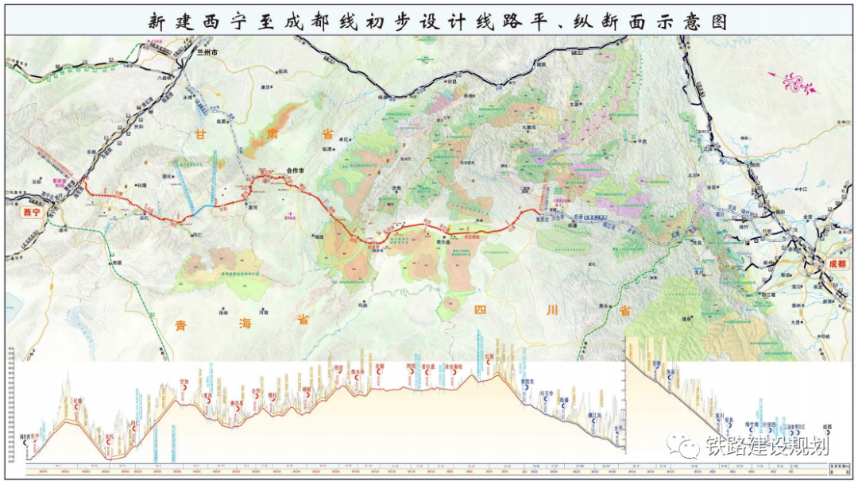

The Xining-Chengdu high-speed railway is part of the Lanzhou-Xi’an-Guangzhou corridor of my country’s “eight vertical and eight horizontal” high-speed railway network. It spans the three provinces of Qinghai, Gansu and Sichuan. 60% of the line is located above 3,000 meters above sea level, which makes construction extremely difficult. In particular, tunnel construction requires long-term exposure to altitude sickness and large temperature differences between day and night, which is a huge challenge for manual operations and transportation.

Based on the advantages of the entire industry chain and rich welding application experience, STEP Robotics provides efficient, intelligent and flexible arch frame production solutions for the construction of the Xicheng high-speed railway tunnel, helping China’s rail transit to develop by leaps and bounds.

Double-machine collaboration, efficient production

Production process

H-shaped steel is automatically transmitted to the arch bending machine through the track for arch bending

After the arch frame is formed, the workpiece size is determined by laser recognition technology and then cut by the robot

The welding robot determines the shape and position of the workpiece through 3D vision, and then transmits it to the handling robot through Ethernet for assembly

After assembly, the welding robot will position the welding workpiece as a whole, and then weld the main position of the workpiece

The master-slave control technology of the Xinshida robot enables the welding robot and the handling robot to cooperate with each other for efficient production; at the same time, the dual robot and dual station design is adopted to double the efficiency; the dual-platform stereotyped template design effectively guarantees the welding accuracy and processing efficiency, and can realize cyclic processing.

Adaptive flexible welding, reliable and consistent quality

The welding workspace is reconstructed through visual sensing, the workpiece position is identified, and the welding robot moves accurately to the initial welding position. The STEP welding robot SA6/1400 perfectly matches the standard arc welding task with its 6kg load and 1400mm working radius. The streamlined design of the robot wrist ensures that the robot has the smallest destructive contour and the highest degree of freedom of movement. Real-time detection and pre-processing during welding, online correction of the robot’s motion trajectory and automatic adjustment of welding process parameters, beats 20% higher than traditional contact positioning and line laser positioning, and can be compatible with workpieces with deviations of more than 100mm, ensuring the consistency and high reliability of weld formation and welding quality.

Solving the labor shortage and achieving the fastest delivery

For the production of tunnel H-shaped steel arch frames, the demand for operating technicians is increasing, and the advantages of STEP’s intelligent welding system over traditional arch frame welding are prominent.

Using robots as carriers, highly flexible intelligent welding that replaces manual labor is realized.

Compared with manual labor, it has higher work efficiency and more reliable welding quality.

All points are generated by vision, and the whole system can be put into operation quickly.

Customer voice

“Because the project is located in a remote area and the environment is harsh, it is difficult to recruit workers. The high-quality products and services of the STEP robot have solved our worries. The high stability of the robot and the 24-hour rapid response service provide us with stable and timely delivery capabilities. This is why we finally chose STEP.” The project leader said.

As a pioneer in the application of robot welding, STEP has taken the lead in many market segments. This time, STEP Robot has greatly expanded the application boundaries of welding robots with the technical advantages of the 3D vision-guided intelligent welding system, meeting the new needs of the rail transit industry for intelligent welding.

In the future, STEP will continue to work with partners in the subdivided industries to break through more welding technical difficulties, incubate more competitive welding solutions, empower partners, and jointly promote the progress and development of domestic robot welding.

Related product recommendations:

GE IS220PPDAH1A REV E

HONEYWELL TC-PPDO11

ABB PPD113 B01-10-150000 3BHE023784R1023

GE IS220PPDAH1B

Honeywell TK-IAH161 TK-OAV081 TK-PPD011

ABB PPD113-B03-23-111615

ABB PP D113 PPD113 3BHE023784R2630 B01-26-111000

HONEYWELL TC-PPD011

ABB PPD512 A10-15000

ABB PPD113B03-26-100100 3BHE023584R2625

ABB PPD113B03-26-100110 3BHE023584R2634

ABB PPD512A10-150000

ABB PPD113B01-10-150000 3BHE023784R1023

ABB PPD113B03-26-100110 3BHE023584R2634

ABB PPD113B01-10-150000 3BHE023784R1023

ABB 3BHE020570R1022 PPD114 B1022 AC 800PEC

ABB PM891K01

ABB PM863K01 3BSE088381R1

ABB PM858K02, 3BSE082896R1

ABB PM860K01

ABB PM861K01 3BSE018105R1

ABB PM861AK01

ABB PM864A 3BSE018162R1

ABB PM803F 3BDH000530R1 CDIO 16/16-0,5 BERGHOF

S-073N 3BHB009884R0021 35SHY3545L0014

S-053M 3BHB012897R0003

S-073N 3BHB009884R0021 35SHY3545L0014

S-073N 3BHB009884R0021

More…

Leave a comment

Your email address will not be published. Required fields are marked *