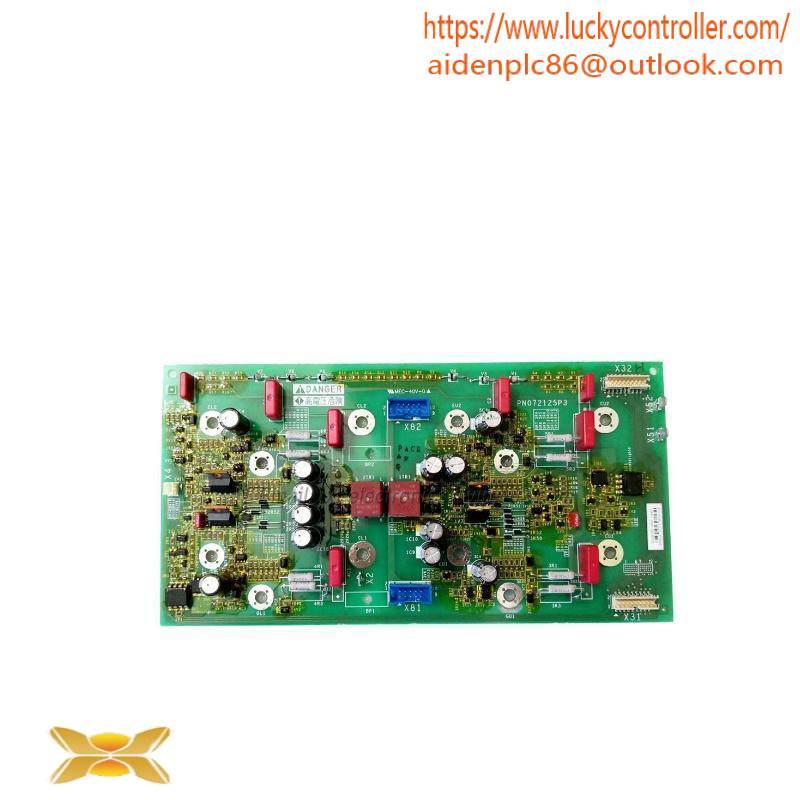

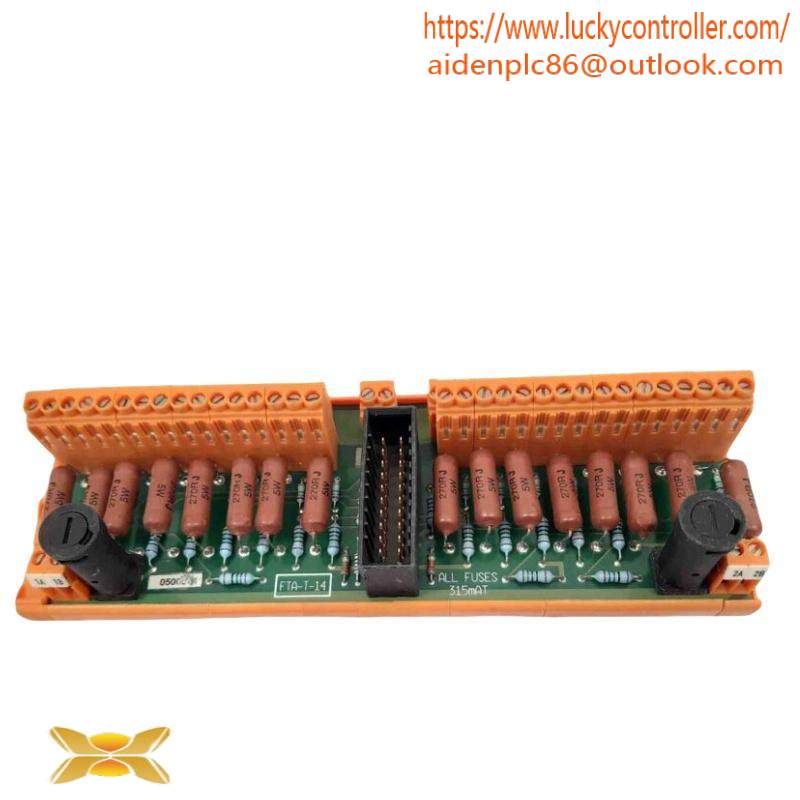

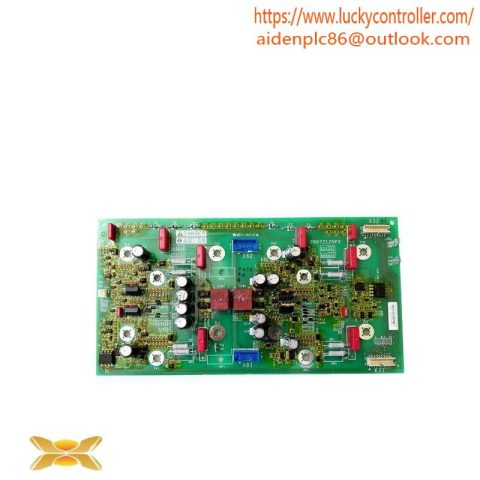

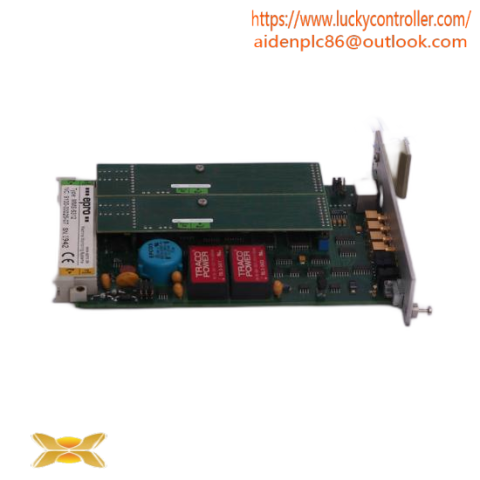

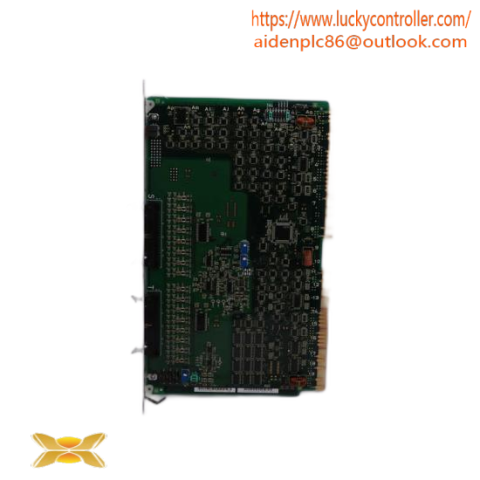

It is formed by printing circuit line patterns on an insulating substrate using conductive materials such as copper. It provides reliable electrical connections and support for electronic components, and its application range covers a wide range of fields from household appliances to aerospace equipment. VTM branch line printed circuit board is a specific type of it, usually used to meet specific electrical connection and signal transmission needs.

Function:

Signal transmission: Signal transmission between electronic components is achieved through circuit lines printed on the substrate.

Power supply: The VTM branch line printed circuit board provides stable power input for electronic components to ensure normal operation of the equipment.

Support components: The VTM branch line printed circuit board serves as a carrier for electronic components and provides stable mechanical support.

Structure:

Insulating substrate: The VTM branch line printed circuit board is made of composite materials such as glass fiber reinforced epoxy resin as a support and insulating layer.

Conductive lines: The VTM branch line printed circuit board is a conductive material line such as copper printed on an insulating substrate, which is used to achieve connection between electronic components.

Component installation position: The component installation position is set on the circuit board so that various electronic components can be soldered or inserted into the circuit board.

Features and advantages

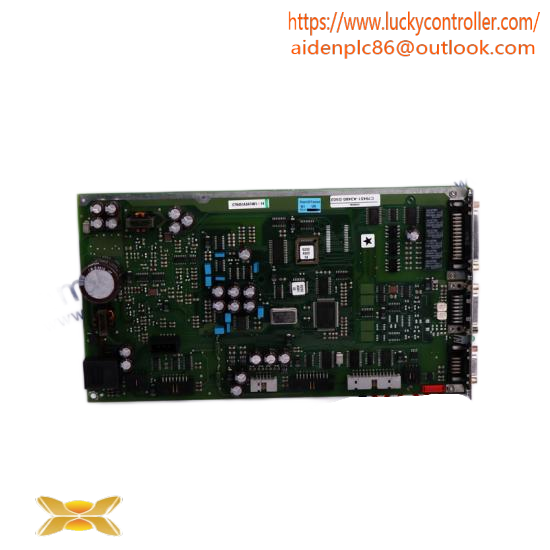

High efficiency: The VTM branch line printed circuit board adopts advanced production technology and materials, with efficient signal transmission capability and stable power supply performance.

High reliability: After strict quality control and testing, the reliability and stability of the circuit board are ensured, and the equipment failure rate is reduced.

Easy to maintain: The modular design makes electronic components easy to replace and maintain, reducing maintenance costs and time.

Strong adaptability: The VTM branch line printed circuit board can be customized according to different needs and application scenarios to meet the connection requirements of different devices.

Application scenarios

The VTM branch line printed circuit board is widely used in various electronic devices, such as:

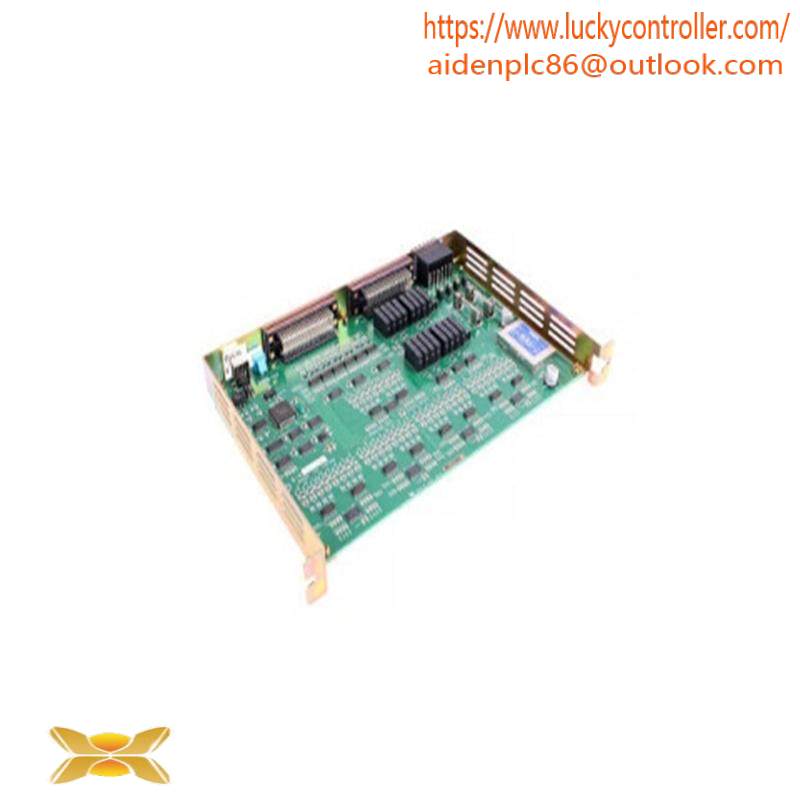

Communication equipment: The VTM branch line printed circuit board is used to realize the circuit board of signal transmission and data exchange.

Computer equipment: The VTM branch line printed circuit board is used to connect the circuit board of electronic components such as processors, memory, input and output devices.

Industrial control equipment: The VTM branch printed circuit board is used to realize industrial automation control circuit boards, such as PLC (programmable logic controller), etc.

Consumer electronic devices: such as mobile phones, tablets, TVs, etc., circuit boards used to connect components such as display screens, cameras, batteries, etc.

Development trend

With the advancement of technology and the continuous emergence of emerging markets, VTM branch printed circuit boards are developing in the following directions:

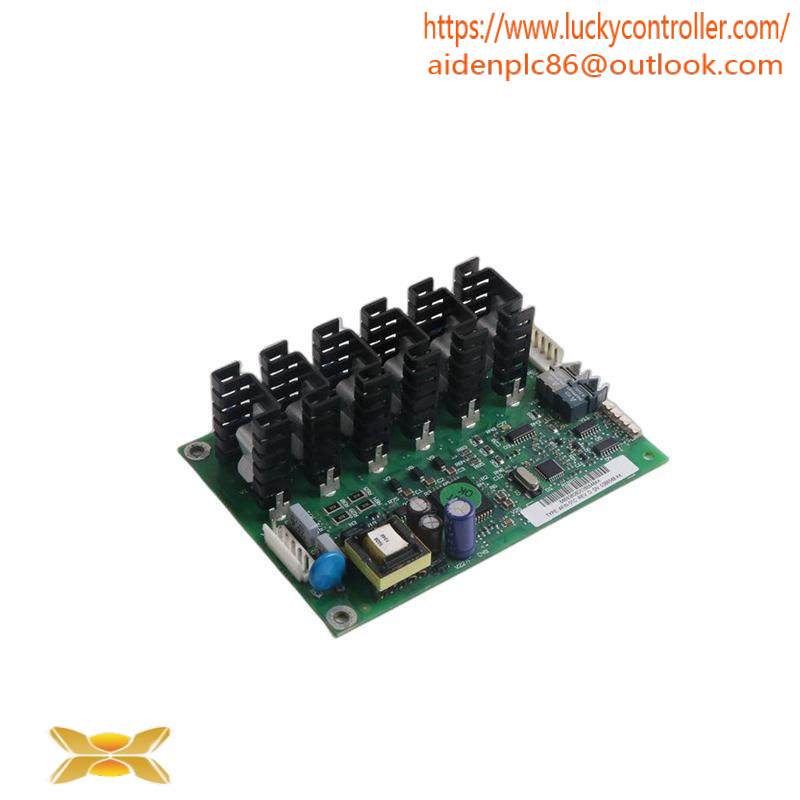

High density: The VTM branch printed circuit board adopts more advanced production processes and materials to improve the integration and density of circuit boards and achieve more complex connection requirements.

High performance: The VTM branch printed circuit board improves the signal transmission speed and stability of the circuit board to meet the needs of high-speed data transmission and real-time control.

Green manufacturing: Focus on environmental protection and sustainable development, use environmentally friendly materials and processes, and reduce energy consumption and waste emissions in the production process.

Intelligent: Combine new technologies such as the Internet of Things and artificial intelligence to achieve intelligent management and maintenance of circuit boards and improve the reliability and efficiency of equipment.

There are no reviews yet.